Award Winning Service

Award Winning Service

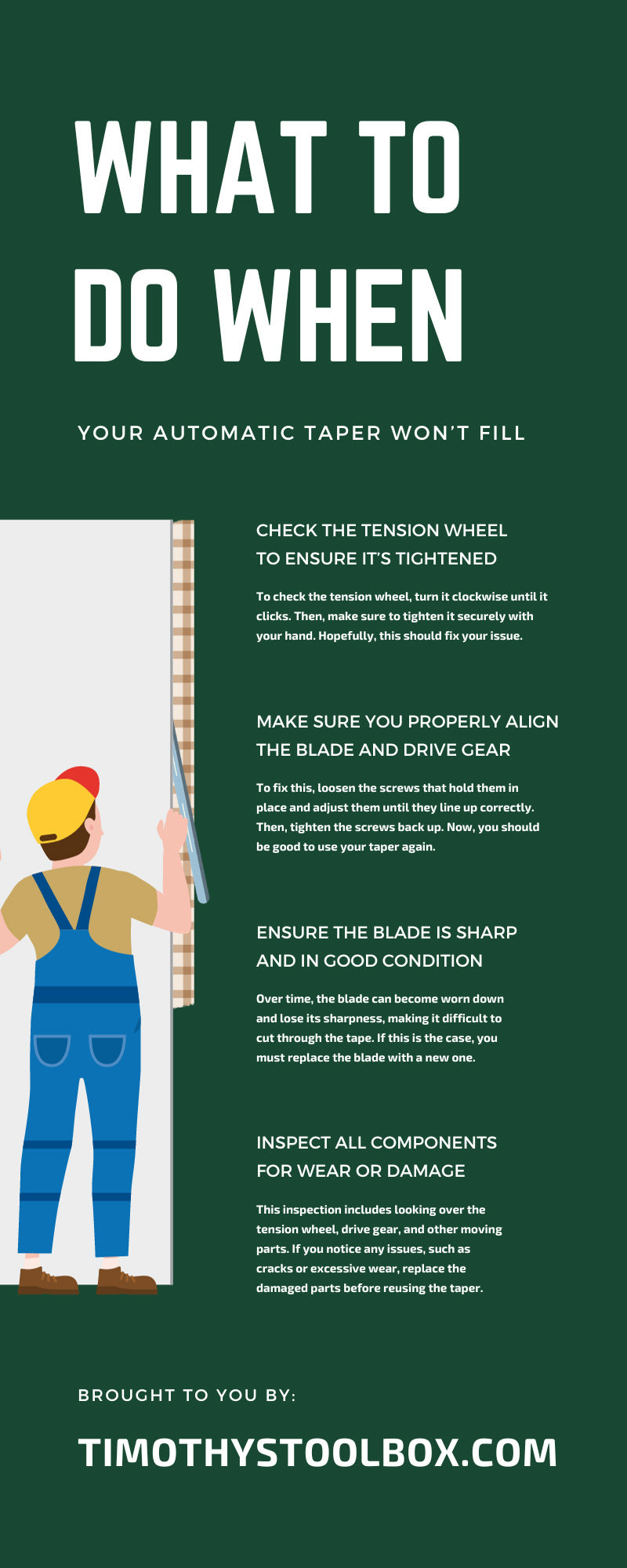

Are you having trouble getting your automatic taper to fill correctly? Are you looking for a solution that will enable you to stop wasting time and start finishing the job more quickly?

Don’t let a malfunctioning automatic taper get between you and your project’s completion. These helpful tips will show you what you need to do when your automatic taper won’t fill and how to troubleshoot the issue.

The tension wheel is a crucial component in the automatic taper that controls the rate at which you dispense the tape. You may have issues filling and dispensing the tape if you don’t have it engaged and tightened correctly. To check the tension wheel, turn it clockwise until it clicks. Then, make sure to tighten it securely with your hand. Hopefully, this should fix your issue.

A common cause of filling issues with an automatic taper is when you don’t have the blade and drive gear properly aligned. This can happen if they become dislodged or misaligned during use. To fix this, loosen the screws that hold them in place and adjust them until they line up correctly. Then, tighten the screws back up. Now, you should be good to use your taper again.

Another possible reason for your automatic taper not filling properly is a dull or damaged blade. Over time, the blade can become worn down and lose its sharpness, making it difficult to cut through the tape. If this is the case, you must replace the blade with a new one.

In addition to the blade, you must regularly inspect all components of your automatic taper for signs of wear or damage. This inspection includes looking over the tension wheel, drive gear, and other moving parts. If you notice any issues, such as cracks or excessive wear, replace the damaged parts before reusing the taper.

Like any tool, an automatic taper requires regular maintenance to keep it functioning properly. One important aspect of this is cleaning and lubricating the taper regularly. This step will prevent debris buildup and ensure all parts are moving smoothly.

In addition to regular cleaning and lubrication, you need to periodically check for any debris or dirt that may have accumulated inside the automatic taper. This debris can clog up the machine and prevent it from properly filling and dispensing the tape. Use compressed air or a small brush to clean out any debris.

If you have tried all of these troubleshooting steps and your automatic taper still won’t fill correctly, try using a different roll of tape. Sometimes, the issue may be with the quality or compatibility of the tape rather than the machine itself.

If you have exhausted all troubleshooting options and your automatic taper still won’t fill correctly, it may be time to seek professional help. An expert in automatic taper repair will be able to diagnose and fix any underlying issues with your machine so that you can get back to work without further delays.

There are a few things to remember when searching for an expert to repair your automatic taper. We outline a few of them below.

When seeking repair services for your automatic taper, the technician’s expertise and experience are paramount. They should be well-versed in handling different makes and models of automatic tapers and deeply understand their mechanisms. Look for a service provider with a proven track record in delivering effective repair solutions and high customer satisfaction rates.

Downtime can be costly, especially if you rely on your automatic taper for daily operations. Choose a service provider who offers prompt response times and efficient problem resolution. It helps if they provide on-site services or pick-up and drop-off options to minimize disruption to your schedule.

A service warranty is a testament to a business’s confidence in their quality of work. It also gives you peace of mind knowing that they will address any post-repair issues without additional costs. Opt for a service provider offering a satisfactory repair warranty period.

Clear communication and transparency about costs and repair processes are also important factors. A good service provider should be able to explain what’s wrong with your automatic taper and how they plan to fix it in terms that you can understand. They should also provide a detailed quote upfront. This way, you’ll avoid unexpected costs.

A repair service is only as good as the quality of the parts they use. Check if the service provider can access genuine, high-quality parts for your automatic taper. Using subpar parts could cause further issues down the line and affect the performance and longevity of your tool.

Lastly, look at the company’s reputation. Check online reviews and ask for recommendations from others in your field. Positive testimonials from satisfied customers can provide reassurance and insight into the company’s dependability, professionalism, and quality of service.

Taking care of your automatic taper isn’t a one-time task. It’s a continuous process that demands attention and regular maintenance. If your automatic taper doesn’t fill, you can fix this issue by inspecting and cleaning your tool and ensuring its parts are in good condition. However, even with meticulous care, issues may arise. If you can’t troubleshoot and resolve the problem, seeking professional help is the best course of action.

If you’re looking for automatic drywall taping tools, Timothy’s Toolbox has you covered. All of our products focus on quality and efficiency, ensuring a smooth taping experience every time. With our range of automatic tapers, corner rollers, and other drywall tools, we have all your finishing needs covered. Shop now and take your finishing game to the next level.

{"one"=>"Select 2 or 3 items to compare", "other"=>"{{ count }} of 3 items selected"}

Leave a comment